Eng. Philip Holi, Technical Director, Davis & Shirtliff

By Philip Holi;

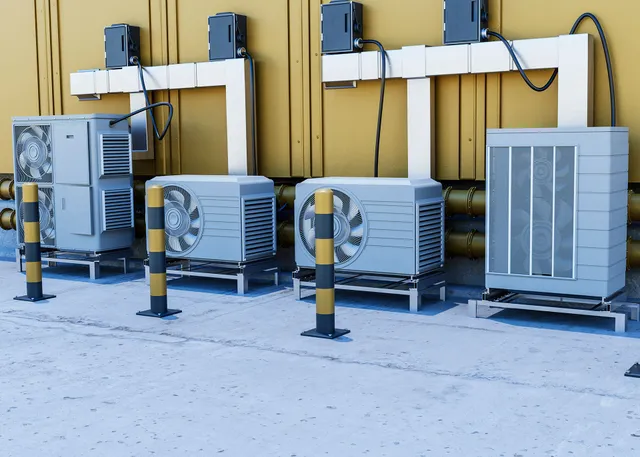

The landscape of pump technology has evolved significantly over the past decade, driven by the need for higher efficiency, reduced operational costs, and enhanced reliability. Modern pump systems now integrate advanced components like permanent magnet high-efficiency motors, embedded smart controllers, variable frequency drives (VFDs), and IoT capabilities.

These innovations are transforming traditional pump operations, offering unprecedented levels of control, energy savings, and system optimization.

1. Permanent Magnet High-Efficiency Motors

Permanent magnet (PM) motors are gaining popularity in pump applications due to their superior efficiency compared to conventional induction motors. Key benefits include:

High Efficiency: PM motors typically achieve efficiencies greater than 90%, even under partial load conditions. This is due to their ability to eliminate the energy losses associated with rotor windings in traditional motors.

Compact Design: These motors offer higher power density, allowing for a more compact and lightweight pump design without sacrificing performance.

Reduced Operating Costs: The higher efficiency of PM motors leads to significant energy savings, especially in applications where pumps run continuously or under variable load conditions.

PM motors are particularly effective in scenarios where energy consumption is a critical concern, such as in HVAC systems, water treatment plants, and industrial processes.

2. Embedded Smart Controllers

The integration of embedded smart controllers into pump systems has revolutionized the way pumps are monitored and controlled. These controllers offer several advanced features:

Real-Time Monitoring: Embedded controllers continuously monitor key pump parameters such as pressure, flow rate, and temperature, allowing for immediate detection of anomalies.

Automatic Adjustments: Smart controllers can automatically adjust pump operation based on real-time conditions, optimizing performance and energy use.

Predictive Maintenance: By analyzing data trends, embedded controllers can predict potential failures and schedule maintenance before a breakdown occurs, minimizing downtime.

The use of embedded smart controllers is particularly beneficial in complex systems requiring precise control, such as in chemical processing or water distribution networks.

3. Variable Frequency Drives (VFDs)

Variable frequency drives (VFDs) are now a standard feature in modern pump systems, offering significant improvements in energy efficiency and operational flexibility. Key advantages of VFDs include:

Energy Savings: VFDs allow pumps to operate at varying speeds, matching output to demand. This reduces energy consumption, especially in applications where pump load fluctuates, such as in irrigation or HVAC systems.

Soft Start and Stop: VFDs enable pumps to start and stop gradually, reducing mechanical stress and extending the lifespan of the pump and associated piping.

Flow and Pressure Control: VFDs provide precise control over pump output, ensuring that the system operates within optimal parameters, which is crucial in maintaining consistent pressure in water supply systems.

The adoption of VFDs has become essential in industries looking to enhance energy efficiency and reduce operational costs.

4. Internet of Things (IoT) Integration

4. Internet of Things (IoT) Integration

The Internet of Things (IoT) has brought about a paradigm shift in pump technology, allowing for remote monitoring, control, and data analytics. IoT-enabled pumps offer a range of benefits:

Remote Monitoring: IoT integration allows operators to monitor pump performance from anywhere, using cloud-based platforms. This is particularly valuable in remote or hard-to-access locations.

Data Analytics: IoT devices collect and analyze data in real-time, providing insights into pump performance, efficiency, and potential issues. This data-driven approach helps in making informed decisions and optimizing system performance.

Predictive Maintenance: IoT systems can predict maintenance needs based on real-time data and historical trends, reducing unexpected downtime and maintenance costs.

IoT-enabled pumps are transforming industries by providing smarter, more responsive systems that can adapt to changing conditions and requirements.

5. Synergy of Advanced Technologies

The integration of PM motors, embedded smart controllers, VFDs, and IoT capabilities creates a powerful synergy that enhances the overall efficiency and reliability of pump systems. This advanced technology stack enables:

Energy Optimization: Combining high-efficiency motors with VFDs and smart controls leads to significant energy savings, making pump systems more sustainable and cost-effective.

Enhanced Reliability: Predictive maintenance and real-time monitoring reduce the risk of unexpected failures, ensuring continuous operation in critical applications.

Operational Flexibility: Smart controllers and VFDs allow for dynamic adjustments in pump performance, providing flexibility to meet varying demand conditions without compromising efficiency.

Remote Management: IoT integration facilitates remote management, allowing operators to oversee multiple pump systems from a central location, improving operational efficiency and response times.

6. Applications and Future Trends

The advancements in pump technology are being widely adopted across various sectors, including water and wastewater management, industrial processes, oil and gas, and HVAC systems. The trend towards smart, energy-efficient, and remotely manageable pumps is expected to continue, driven by increasing demands for sustainability and operational efficiency.

Future developments may include further enhancements in AI-driven analytics for even more precise control and optimization, as well as greater integration with renewable energy sources, such as solar-powered pumps equipped with advanced battery storage systems.

The Author is the Technical Director, Davis & Shirtliff