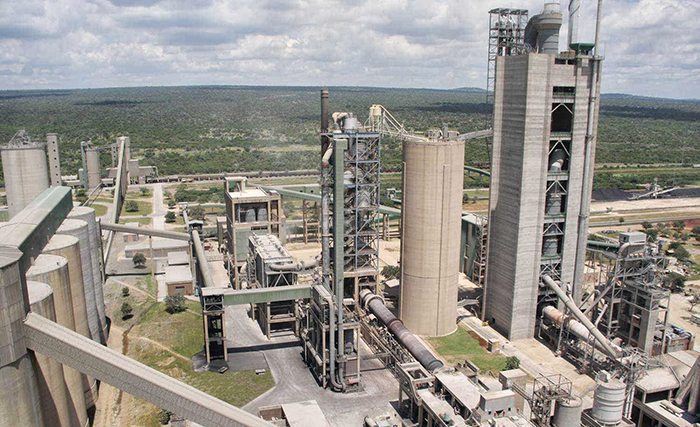

The ongoing kiln shell replacement is expected to sustain EAPC-PLC competitiveness in the market.[Photo/EAPC}

East African Portland Cement Plc has commenced the replacement of its kiln shell as it seeks to increase its productivity to over 1400 tonnes per day.

The firm’s burning zone which has been operating since 1996 has been damaged for quite some time and this has resulted in product shortage in the market as a result of difficulties with the dilapidated equipment in the clinkering process.

“Due to the high costs of energy and an old clinker line, the board has prioritized efficiency and reliability of our integrated plant operations to drive cost optimization,” said Oliver Kirubai, EAPC-PLC MD.

The project, expected to last 45 days begun with pre- shutdown activities in June 2022 and officially kicked off on July 25.

The nerve of East African Portland Cement operations is the kiln where a raw mix of limestone, kunkur, bauxite and iron-ore is fed and burned up to 1450 °C to form clinker which is the intermediate product of cement.

The 54m long kiln is divided into different zones reflecting different reactions taking place, at the extreme exit end is the burning zone where hot gases are intensive.

The burning zone which is extensively damaged will see a replacement of 16.5 meters section in the ongoing kiln shell replacement project.

Kenya currently has 13 cement plants with only 4 cement plants with integrated clinkering and capabilities.

The ongoing kiln shell replacement is expected to sustain EAPC-PLC competitiveness in the market.

According to Head of Plant Operations at EAPC-PLC, Stanley Irungu, the Blue Triangle Cement will still be available and customers will continue enjoying provision of quality cement as the kiln upgrade project continues.

1 thought on “East African Portland Plc seeks to increase productivity,replaces Kiln shell”